How do we validate e-drive and e-axle prototypes at Bosch Research?

Bosch Research Blog | Posted by Jochen Fassnacht, Timo Bartsch, Matthias Kränzler and Wael Hilali, 2022-09-15

Climate change and the need to reduce CO₂ emissions are significant drivers for electrification. In addition to reduced CO₂ emissions, sustainability and affordability of new e-drives are essential. This requires reliable, durable and efficient e-drive and e-drive component solutions that save resources and raw materials and are easy to manufacture. These factors have led to a variety of innovations in new electric motors, new axles, and new high-performance electronics.

The V-model of development entails not only market studies, requirement analyses and derivations, as well as system, subsystem and component designs and simulations, it also demands prototypical and production sample evaluations of the concepts and products on the test bench. Since building and testing real sample prototypes involves about five to ten times more man-hours than simulation, there is a strong desire to virtualize the design and evaluation of component and system concepts with simulation.

But even with advanced simulations, real measurements are still needed and will be needed in the foreseeable future to verify the results and truly validate the concepts and products. The complete eDrive consists of an electrical, mechanical and thermal system with a multitude of couplings between them. These linked systems are also at least partly non-linear and have highly different time constants and several diverse and complex control concepts.

This provides insight into the complexity of the system and explains why it is not possible to model all relevant effects in the simulation in sufficient detail for validation. In order to improve the simulation and to enable better modelling of components, subsystems and systems in the future, test bench measurements are again required.

To validate new component and system concepts for electric drives and to create and parametrize new simulation models, a variety of different measurements are necessary. These range from “simple” tests of individual components in stationary operation to the measurement of complete powertrain concepts in real driving cycles or during real dynamic driving in motion maneuvers. This requires a very flexible test bench with a very agile control system and efficient handling of the measurement data.

In addition, a versatile and easily adaptable set of relevant components is required. For example, in order to test an e-machine for e-mobility, you also need a fitting inverter with a suitable control system. Or if you want to test a new semiconductor concept for traction inverters, you need a proper e-machine.

A strong new and emerging field of application is the use of artificial intelligence for the control, diagnosis and sensing technology of electric drives. This naturally leads to new additional and very demanding requirements such as the automated operation of the test bench over long periods of time to enable learning and data generation. Artificial intelligence applications very often require high computing power. Therefore, the electronic control unit of the prototype must provide this power or a real-time interface to a very powerful computer is required.

As mentioned earlier, there are a multitude of completely different innovations in e-drive technology that are currently being developed and more are expected soon. These new concept ideas have extremely different boundary conditions and requirements in terms of cooling, control performance and drive interfaces, speed, torque, supply voltage, sensor signal evaluation and so on. To evaluate these different concepts, many measurement sensors must be integrated and efficiently assessed.

The measurement signals for concept evaluation include various currents, voltages and temperatures at widely diverse positions of the electrical machine, the gearbox and the inverter, noises, vibrations at different positions and speeds, torques, power at different positions and efficiencies of the various components.

There are well over 100 different signals, sometimes over long periods of time, which have to be recorded, stored and subsequently evaluated with sufficiently synchronized sampling rates. This is also a challenge from a data processing perspective. In future artificial intelligence applications will increase this challenge significantly, as a large amount of data is needed for data-driven models.

The operation of such a high-power e-drive and e-axle test bench demands safe handling of the occurring high torques, speeds, currents, voltages and temperatures with a suitable and certified safety concept.

How these challenges are tackled at the Bosch Research e-drive and e-axle testbench is discussed below.

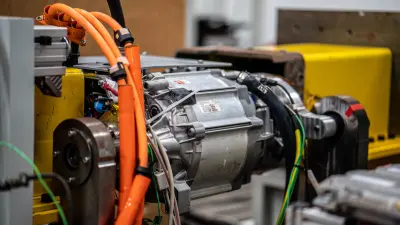

If a single inverter or traction e-machine is to be tested, we use a 250kW, 400 Nm single load machine. The test bench also includes two bi-directional 180kW DC power supplies that can be connected in parallel and provide voltages up to 850V. These DC sources can also replicate batteries and represent the high-voltage network of electric vehicles.

If the device under test is a complete e-axle, this means a combination of inverter, e-machine, transmission and differential gear, we use an e-axle test bench with two 5,500 Nm and 400 kW load machines, which can provide enough torque on wheel speed level to test traction systems.

Series inverters for motor vehicles are inexpensive, efficient, powerful, robust and very reliable. But they are highly optimized for their specific use case or for the requirements of a specific customer in addition to being very inflexible. Rapid prototyping inverters are low-volume products optimized for flexible use, but they are often expensive and not as efficient, reliable and powerful as high-volume automotive inverters.

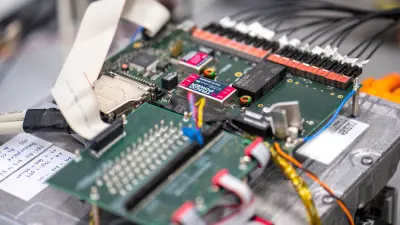

To combine the advantages of both worlds, we use a self-designed adapter board, which enables a performant control of Bosch series and prototype inverters of different generations by a commercially available high performance rapid prototyping system. This concept enables switching frequencies of well over 50 kHz and the use of almost free pulse patterns. At the same time, the safety functions and reliability of the series hardware can be further used. The next illustration shows this self-developed adapter board mounted on a Bosch inverter.

For the control of the complete test stand with load machines, DC sources, cooling/heating and lubrication systems, and the coordination of the recording of the various measurements, we use a commercially available, open and very flexible automation system. This automation system also has the necessary certified safety chain that reacts very quickly in the event of a malfunction and switches off the power to the test stand. This means that it switches off the electrical energy, discharges electrical accumulators and brakes rotating masses. This automation system also enables the testing of equipment in complex driving cycles with automatic control of all relevant auxiliaries such as cooling and lubrication.

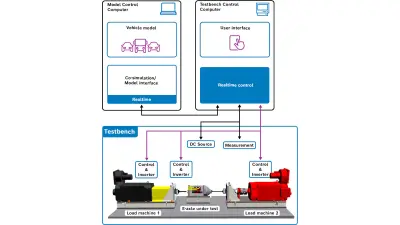

Certainly, it is best to perform measurements with the device under test in its real environment and with the intended use cases. This requires Hardware in the Loop (HiL) simulations where the test bench has to emulate the different environments of the device under test. This ranges from simple speed control of an examinee like an e-machine up to the emulation of complete wheel or vehicle dynamic behavior by one or more suitable load machines. It should be possible to operate the drive or axle on different driving cycles with different vehicles. In addition, the test bench must provide sufficient electrical power and emulate even the behavior of vehicle batteries and provide a suitable cooling power supply.

The HiL integration of an e-axle is briefly described below. This enables the modelling of the entire vehicle and driving situation in the software and the use of a real e-axle within this virtual car environment.

The vehicle model runs on a standard laptop with adequate software. The big issue here is the co-simulation with the real-time interface of the test bench. In stand-alone simulation, it is not critical if a simulation time step takes longer than in real-time. This can happen, for example, when the solver needs more time for calculation or there are background tasks like storing data. The test-bench control demands hard real-time over the complete operation time. At the same time, the vehicle model cannot provide results in advance because these results depend on the real-time information from the test bench.

The solution is to use a sufficiently fast computer for the vehicle model calculation and to reserve enough time for calculation even in worst-case scenarios. Still, there is a small chance that the necessary information will not be available in rare cases. In these instances, the test bench will have to run another timestep with old results if critical limits are not reached. If critical limits are reached, which is even much more seldom, because then a critical operating point must occur with a very rare time delay in the simulation, then the experiment must be aborted and repeated.

The following figure shows a rough overview over the realized HiL concept at the test bench. The used buses are mainly private CAN-buses, which are fast enough for the application.

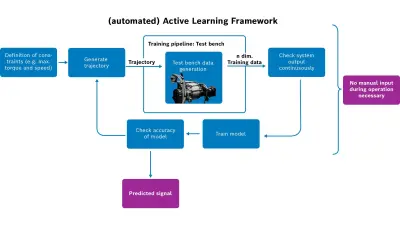

Artificial intelligence is becoming increasingly important in the field of electrification. Data generation for artificial intelligence (AI) algorithms often leads to a high time requirement for test-bench use and thus to high test-bench costs. To meet these new and challenging requirements, we not only use the test bench for AI data generation, but also implement algorithms with integrated AI to improve our data generation process. These algorithms and methods are called safe active learning.

Data generation for AI models is often based on a classical experiment plan (e.g., grid measurements) or on a Design of Experiment (DoE) with a large amount of measurement data. Classically, DoE definition, data generation and AI model training are three separate domains with sequential and manual processing. To improve this process and adapt to the needs of artificial intelligence applications, we are developing a safe active learning approach, which includes all three areas in one automated process and combines this with AI model training. This approach, as shown in the diagram below, involves many steps that in the past had to be performed manually and required a lot of expert knowledge for each area and a deep understanding of the underlying system. With the new approach, only the basic constraints and operational limits need to be defined. The framework then generates trajectories that are likely to have the greatest relevance to the desired AI model, ensuring that critical regions under consideration are avoided during measurement. These short trajectories, called snippets, are then measured at the test bench. The AI regression model is then re-trained with the new measurement data, accuracy is checked, and a new trajectory is calculated based on the re-trained AI model.

In addition to efficient trajectory generation, safe active learning also helps to minimize the shutdown of test benches when they operate in certain ranges that exceed the allowed physical limit of the system, such as critical temperatures or vibrations. For this purpose, we use an entropy-based active learning framework extended by a constraint-inducing safety. For the main regression task, we use Gaussian processes (GP’s) to learn the system behavior from a limited budget of incrementally sampled data points. Our exploration strategy for determining the next query points is based on the differential entropy criteria. We also employ a problem-specific GP classifier to identify safe and unsafe regions. The basic idea of this discriminative GP is to learn a decision boundary between two classes, preferably without sampling a point in the uncertain region. This contributes to an automated, efficient and unsupervised test-bench measurement and AI model training and ensures safe exploration and data generation without risking test-bench damage or time wasted due to unnecessary shutdowns.

We feel future proof with our flexible e-mobility prototype testing concept, even for new applications like data generation for artificial intelligence.

What are your thoughts on this topic?

Please feel free to share them or to contact us directly.

Author: Jochen Faßnacht

Starting at Bosch Research in 2002 Jochen has been working in different positions, business units and technical areas of Bosch. He is currently a senior expert on the development of new traction drives for electromobility at Bosch Research. His responsibilities include the development of new electric traction drive and control systems and their integration into the vehicle system with virtually all related aspects.

Please feel free to share them or to contact me directly.

Author: Timo Bartsch

Timo joined Bosch in the field of electrical engineering in 2007. He is currently responsible for the operation of the test bench for electrical machines and axles in research and advance development. His activities range from continuous technical improvement of the test bench including adaptation to new methods, as well as the development and maintenance of the hard- and software of an interface to combine rapid prototyping systems with series inverters.

Please feel free to share them or to contact me directly.

Author: Matthias Kränzler

Matthias is working as a research engineer in the department for Advanced Vehicle Systems. He joined Bosch Research as a PhD student in 2016. His research focuses on AI algorithms and databased methods with lead applications in the field of the electric powertrain. His responsibilities include the integration of databased methods like active learning to the test bench. Before joining the Smart powertrain team, he developed new powertrain concepts for electrified air mobility within Bosch Research.

Please feel free to share them or to contact me directly.

Author: Wael Hilali

Wael is a research scientist and project lead at Bosch Research in Renningen. After his PhD at the University of Stuttgart, he joined Bosch in 2018 to work on the application of artificial intelligence in the electromobility. Wael’s primary interest is to investigate how prior system knowledge represented in the form of first principles models, encapsulating high level of technical understanding and physical knowledge can be leveraged and infused into machine learning models to develop robust and efficient hybrid AI solutions in the field of electromobility.