Electric Machines – history or still a hot topic?

Bosch Research Blog | Post by Marina Keller, 2021-04-06

The beginnings of electrical machines date back to the early 1900s and are closely related to fundamental research into electricity and electromagnetism. The first usable electric motors whose basic structure and mode of operation are very similar to modern direct current, asynchronous and synchronous motors emerged at the end of the 19th century.

At exactly this time, Robert Bosch founded his workshop for precision mechanics and electrical engineering in Stuttgart. The magneto ignition developed in 1887 was literally the initial spark for many subsequent Bosch products that use electric machines. Prominent examples for automobiles include: the alternator, the electric wiper motor, the ABS motor, the electric steering machine and the electric traction machine in modern e-axles in today's generation of electric vehicles. But Bosch products with built-in electric motors are also very successful in other areas, such as electrical tools, household appliances or the immensely popular e-bike.

This more than 100-year success story is accompanied by countless technical innovations not only in the field of electrical engineering: Improved materials, more efficient manufacturing processes, more precise calculation and design methods, the introduction of electronic control devices and control electronics based on semiconductors, improved cooling methods, more compact and reliable mechanical structures, among many more. All these innovations have led to a continuous increase in the power density and efficiency of electric machines of all types and sizes. And yet, in view of this long history, a question arises today: Do we still need research on electrical machines or has this product already been fully developed?

At the beginning, practically all electric machines – either as a generator or as a motor –ran on the grid and were precisely optimized for this operation. Technically, the three-phase alternating current network prevailed over direct current and one-phase alternating current around 1900. The combination of power electronics together with three-phase electric machines made it possible to decouple the mains frequency from the rotating field frequency in the stator from the 1970s on, which resulted in significantly improved speed control and efficiency. With the invention and further development of electric batteries, many drives in mobile applications were no longer supplied by AC but DC voltage. Particularly in electromobility today, the supply from a DC battery with limited energy content plays a major role.

In addition, we are facing new challenges such as climate change. In order to avoid climate-damaging greenhouse gas emissions in future, we will have to largely eliminate fossil fuels from our energy generation, our mobility – indeed, our entire everyday lives. Electric machines play a central role here, both as generators in wind turbines or as drive motors in electric cars. Furthermore, the CO2 balance must neither begin nor end with the product sold. Saving resources when extracting raw materials and producing assemblies, as well as a sustainable concept for disposal and re-use, imposes new technical requirements on the development of electric machines. This ambitious goal can only be achieved with intensive research at all levels and across all domains.

At Bosch we are researching precisely such new solutions. The permanent magnetically excited synchronous machine is dominating the electromobility market. The permanent magnets on the rotor that are required to generate torque are almost exclusively made of neodymium-iron-boron. Furthermore, all the other requisite rare earth elements, such as praseodymium, dysprosium or terbium, are obtained in a highly complex, energy-intensive and sometimes environmentally harmful manner. And as yet, there is no technically mature and implementable recycling concept for these magnets. We are therefore researching alternative machine concepts that do not require magnets, such as the electrically excited synchronous machine. One disadvantage with this type of machine is that the rotating part operates with electrical power, which in the past required wear-prone brushes. Another research aspect is to replace these brushes with contactless energy transmission systems in order to ensure wear-free and error-free operation in mobile applications on the road.

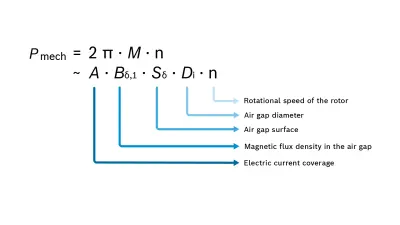

Another goal is to further increase efficiency and power density. Particularly in electric cars, the amount of energy available in the battery limits the achievable range. Consequently, it is important to convert the stored electrical energy into kinetic energy as efficiently as possible. In addition, every gram saved reduces the amount of energy required for acceleration. The mechanical power of an electric machine can only be increased with certain measures, as the following equation shows. The challenges involved in varying these measures will be examined in more detail below.

An increase in the air gap diameter is often not desirable because the installation space is limited and the weight should be minimized. An increase in speed should also be viewed critically. The wheel speed of a car ranges between 1000-2000 min-1. Current traction machines have a maximum speed of 12,000-20,000 min-1.Between electric machine and wheel speed, a mechanical transmission mediates. Higher speeds require additional measures in the gearbox and e-machine to guarantee speed stability. More resilient bearings are required and the efficiency drops, especially in the gearbox. Nonetheless, high-speed drives are an interesting solution in other applications.

Another possibility is to increase the air gap area, i.e., the area between the stationary stator and the rotating rotor. Depending on the installation space, an axial arrangement with a disk-shaped rotor, for example, can be more advantageous than the classic cylindrical structure. In the same way, topologies with two air gaps are currently being investigated, i.e., with two stationary or two rotating components. Such topologies are not new in research, but in terms of their technical implementation and possible commercialization, there are still many unanswered questions, e.g., with regard to the mechanical bearing arrangement, the cooling connection and cost-effective production.

The electric current coverage is closely linked to the current density in the electric machine, i.e., how much current flows across a given area. It is limited by the electrical resistance of the copper used to conduct the electric current, but also by the implemented cooling system. A new and interesting material for increasing the electric current density is graphene as a substitute for copper, whose material properties and applicability in electric motors is the subject of current research at Bosch.

The better the cooling, the higher the current density and thus the higher the torque that can be generated in the same volume. For cooling, new materials with better heat conduction are being researched. But the focus is also on new cooling concepts beyond classic water jacket cooling. Especially in the case of magnet-free electric machines, cooling moving rotors is a great challenge. On the other hand, through new additive manufacturing techniques, conductor cross-sections and winding heads can be optimized in order to reduce power loss and also the cooling effort. At the same time, these new manufacturing processes also offer the potential to reduce the weight of so-called non-active components such as housings and end shields.

The most important tool is precise modeling and calculation of the respective influence factors in the respective domains, but also in their interaction. A large part of the research at Bosch deals with a mathematical description of all relevant effects that is both sufficiently detailed and as efficient as possible. One powerful and universal tool here is numerics in the form of finite element simulation tools. However, there is still a need for research, for example in the efficient calculation of iron losses in electrical steel sheets or in the magnets of electric machines based on fundamental physical principles. Furthermore, these models form the basis for innovative optimization algorithms like free-form optimization of the stator and rotor laminations. Here Bosch also benefits from the expertise it has built up in the field of artificial intelligence at the Bosch Center for Artificial Intelligence in order to incorporate this know-how into specific product improvements.

On a system level, all innovations in the individual components - electric machine, power electronics and transmission - ultimately flow together in the e-axle design. Since Bosch develops and researches all components, interface issues between the domains and components can also be addressed. One example is the reduction of noise emissions of an e-axle through targeted optimization of the power electronics’ switching commands for the single semiconductor switches. Such innovations are only possible through suitable system models and a profound understanding of the physical interdependencies.

Despite the 100-plus-year long history of electrical machine design, there is a lot of unchartered territory to explore. We will face today’s formidable challenges in climate change and sustainability with innovative machine concepts, new break-through technologies, advanced engineering and high-level computation competence. So, let's look forward to the next 100 years of research on electric machines!

What are your thoughts on this topic?

Please feel free to share them or to contact me directly.

Author: Marina Keller

Marina joined the E-Drives and E-Machines group at Bosch Corporate Research in 2017 after finishing her PhD at the institute of electrical energy conversion (iew) at the University of Stuttgart in the field of transverse flux machines for robotic applications. At Bosch, she focuses on modeling and designing electric machines with a special focus on insulation stress, and in recent years, resilience of traction motor windings.